PL Series

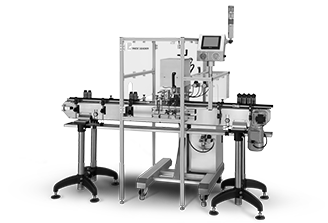

PL-501 Wrap-Around Labeling System

Struggling with slow labeling? Need a compact solution that actually fits your setup? The PL-501 is engineered for flexible productivity and seamless integration into your existing line.

CONFIGURATIONS FOR EVERY PRODUCTION LINE

THE PERFECT FIT FOR YOUR WRAP-AROUND LABELING NEEDS

Tired of slow, inconsistent labeling? The PL-501 delivers precise wrap-around application, saving you time and ensuring your products look their best, every time.

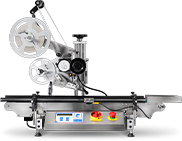

PL-501

Wrap Around Labeling System

PL-501 #3 Wind

Right-to-left product flow and #3 label application.

PL-501/6

6-inch-wide conveyor for wider containers.

PL-501/6 #3

Combines 6-inch conveyor with #3 wind (reverse flow).

PL-501 3M

3-meter conveyor for added line length for side transfers, screw feed indexers, or integrating upstream components.

PL-501 #3 3M

3-meter conveyor plus #3 wind (reverse flow).

PL-501/6 3M

6-inch-wide, 3‑meter conveyor for larger containers and additional space.

PL-501/6 3M #3 Wind

6‑inch-wide, 3‑meter conveyor combined with #3 right‑to‑left flow.

PL-501-3M-NL

3‑meter conveyor with dual label heads for main + neck labels.

PL-501D

Applies crescent‑shaped labels to tapered cups or containers.

PL-501-ZDT

Zero‑downtime labeling with alternating dual label heads.

PL-501-NL

Inline Horizontal Wrap Around Labeling System

PL-501

Wrap Around Labeling System

Need a flexible labeler that adapts to round and flat containers?

The PL-501 is designed to apply pressure-sensitive labels to round bottles, jars, and cans with speed and precision. When production calls for flat-surface labeling, a single tap on the touchscreen shifts the system into one-side mode for boxes or rectangular containers. Its smart speed control adjusts automatically based on the container surface for smooth, consistent application.

Easy setup with intuitive controls

The PL-501 makes changeovers fast with a user-friendly interface and built-in guidance. Operators can access on-screen instructions, memory presets, and troubleshooting tips with ease. Hand wheels make mechanical adjustments simple, keeping downtime to a minimum and output high.

Built to last in real-world conditions

Constructed from GMP-compliant 304 stainless steel and anodized aluminum, the PL-501 is ready for tough environments and long production runs. Its clean design and rugged materials make maintenance quick and straightforward, extending the life of your investment.

If your product line includes round or flat containers, the PL-501 gives you the versatility, control, and reliability to keep labeling efficient and accurate.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Dimensions

- Dimensions: L-W-H: 79” x 40” x 41” (2006mm x 1016mm x 1041mm)

- Maximum Label Size: 6” x 11.8” (152mm x 300mm)

- Maximum Container Width: 4” (101mm) *6” (152mm) Optional

- Conveyor Width: 3.25” (82.55mm)

- Conveyor Height: 31.75-47.75” (806-1213mm)

- Spool Diameter: 14” (356mm)

- Inner Core: 3” (76mm)

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

Show More ˅

PL-501 #3 Wind

Right-to-left product flow and #3 label application.

Customize Your Labeling Workflow with the PL-501/#3 Wind for Optimal Efficiency

Choosing the right labeling machine for your production line is essential for efficiency and consistency. The PL-501/#3 Wind configuration offers a specialized alternative to the standard PL-501, designed for operations that require a right-to-left product flow and #3 label application. While it maintains the same high-performance specs as the base model, this configuration ensures seamless integration into workflows with different product handling needs.

Key Benefits & Features:

- Right-to-Left Labeling: Ideal for production lines requiring reverse product flow.

- Compatible with #3 Labels: Tailored for applications using #3 labels instead of the standard #4.

- Same Trusted Performance: Maintains all the precision, durability, and efficiency of the base PL-501.

- Seamless Integration: Works with your existing production setup without compromising speed or accuracy.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501/6

6-inch-wide conveyor for wider containers.

Expand Your Labeling Capacity with the PL-501/6 for Wider Containers

Built with a 6-inch-wide conveyor, the PL-501/6 lets you handle a broader range of container sizes, making it ideal for lines that must accommodate everything from small bottles to large gallon jugs. You get the same trusted functionality of the standard PL-501 with additional room to grow.

Key Benefits & Features

- 6-Inch Conveyor: Accommodates larger or more varied container widths.

- Consistent Wrap-Around Precision: Maintains accurate placement at higher speeds.

- Versatile for Multiple Industries: Commonly used in chemical, food and beverage, and pharmaceutical.

- Easy Changeovers: Adjust for different product widths without losing efficiency.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501/6 #3

Combines 6-inch conveyor with #3 wind (reverse flow).

Combine Wider Conveyors and Reverse Flow in One Efficient System

By merging the 6-inch-wide conveyor with #3 wind (right-to-left flow), the PL-501/6 #3 delivers enhanced flexibility for unique production layouts. Handle bigger containers while integrating seamlessly with workflows oriented in reverse.

Key Benefits & Features

- Wider Conveyor & Reverse Flow: Two specialized features in one configuration.

- Right-to-Left Product Handling: Ideal if your line demands an alternate flow direction.

- High-Volume Capability: Accommodates both larger containers and higher throughput needs.

- Same PL-501 Reliability: Inherits the performance and precision of the base model.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501 3M

3-meter conveyor for added line length for side transfers, screw feed indexers, or integrating upstream components.

Extend Your Production Line with the PL-501 3M for Added Conveyor Space

Equipped with a 3-meter conveyor, the PL-501 3M is perfect for operations requiring additional room for side transfers, screw feed indexers, or integrating upstream components. It maintains the PL-501’s reputation for speed and precision while offering more space to accommodate complex setups.

Key Benefits & Features

- 3-Meter Conveyor: Increased space for side transfers or upstream additions.

- Ideal for High-Volume Lines: Great for beverage fillers or where multiple containers feed at once.

- Flexible Integration: Fits easily into existing lines needing extra conveyor length.

- Reliable Performance: Retains all the core labeling accuracy of the standard PL-501.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501 #3 3M

3-meter conveyor plus #3 wind (reverse flow).

Achieve Reverse Flow and Extended Conveyor in One Versatile Machine

The PL-501 #3 3M combines the 3-meter conveyor with the #3 (right-to-left) wind, providing maximum adaptability in product handling. It’s the solution for facilities requiring added conveyor length alongside a non-traditional product flow.

Key Benefits & Features

- Long Conveyor & Reverse Flow: Ideal for complex production lines with specific layout needs.

- Simplified Side Transfers: More space enables additional upstream or downstream components.

- Maintains PL-501 Efficiency: All the speed and labeling accuracy you expect.

- Reduced Downtime: Streamlined workflow for faster changeovers.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501/6 3M

6-inch-wide, 3‑meter conveyor for larger containers and additional space.

Wider and Longer: The PL-501/6 3M for Heavy-Duty Production Demands

This configuration merges the 6-inch-wide conveyor with a 3-meter length, giving you both the capacity for larger containers and the extra space needed for side transfers or multi-container feeding. If your line handles a broad range of container sizes at scale, the PL-501/6 3M is a perfect fit.

Key Benefits & Features

- 6-Inch, 3-Meter Conveyor: Accommodates large or varied containers while providing extra line length.

- Versatile Application: Adaptable to food, beverage, chemical, or pharma workflows.

- Seamless Integration: Easily fits into high-throughput production lines.

- Retains Base Model Performance: Preserves the accuracy and reliability of the standard PL-501.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501/6 3M #3 Wind

6‑inch-wide, 3‑meter conveyor combined with #3 right‑to‑left flow.

Maximize Flexibility: Larger, Longer, and Reverse Flow All in One

By blending a 6-inch-wide, 3-meter conveyor with the #3 right-to-left flow, this all-in-one configuration meets the most demanding production requirements. It’s perfect for facilities that handle large containers, need extra conveyor length, and run lines in reverse orientation.

Key Benefits & Features

- Ultimate Versatility: Wider conveyor, extended length, and reverse flow combined.

- Adaptable for Complex Systems: Room for integrations like side transfers or multi-container feeds.

- Efficient Layout: Accommodates non-standard line directions without sacrificing speed.

- Top-Tier Performance: Delivers the same PL-501 precision and reliability.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

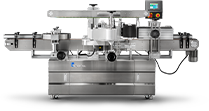

PL-501-3M-NL

3‑meter conveyor with dual label heads for main + neck labels.

Label Bottles with a Neck Label in One Pass Using the PL-501-3M-NL

Designed specifically for neck labels (like beer or specialty beverage bottles), this configuration adds a second label head for precise neck label placement. The extended 3-meter conveyor ensures enough line space for positioning, making it a strong choice for multi-label applications.

Key Benefits & Features

- Dual-Label Capability: Ideal for applying main and neck labels simultaneously.

- 3-Meter Conveyor: Extra space for proper container spacing and positioning.

- Accurate Neck Label Placement: Ensures brand consistency for beverage and specialty products.

- Fully Featured PL-501: Retains the base model’s speed, precision, and easy operation.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501D

Applies crescent‑shaped labels to tapered cups or containers.

Tackle Tapered Containers with the PL-501D for Custom Cup Labeling

Engineered for tapered cups or containers, the PL-501D applies crescent-shaped labels with precision. This specialization is perfect for soup cups, deli containers, or any vessel that narrows toward the bottom.

Key Benefits & Features

- Tapered Cup Labeling: Designed specifically for conical or tapered surfaces.

- Consistent Application: Ensures the label stays flat and wrinkle-free around the taper.

- Brand Versatility: Supports custom ‘rainbow’ or crescent-shaped labels.

- High Throughput: Delivers fast labeling without compromising accuracy.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

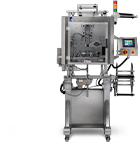

PL-501-ZDT

Zero‑downtime labeling with alternating dual label heads.

Zero Downtime Labeling: Keep Production Moving with the PL-501-ZDT

Featuring two label heads that alternate when one runs out of labels, the PL-501-ZDT virtually eliminates stops for roll changes. Ideal for high-volume lines where every minute of uptime matters.

Key Benefits & Features

- Dual Label Heads: Automatic switching ensures continuous labeling.

- Perfect for Large Runs: Ideal for operations handling high production speeds.

- Minimize Downtime: Swap label rolls on one head while the other keeps working.

- Same PL-501 Reliability: Consistent application and user-friendly controls.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

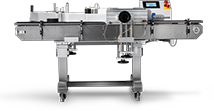

PL-501-NL

Inline Horizontal Wrap Around Labeling System

Need reliable body and neck labeling for round containers?

The PL-501-NL is purpose-built for the food and beverage industry, applying pressure-sensitive labels to bottles and jars with precision. Whether you're labeling the body, the neck, or both, this machine adjusts to your product shape and speed, delivering a clean, consistent finish. Optional front-and-back labeling lets you scale up your presentation without switching machines.

Designed for quick setups and flexible changeovers

The PL-501-NL makes fine-tuning easy with straightforward controls and operator-friendly features. Adjustments for different container sizes or label types can be completed quickly, keeping your team efficient and production on schedule.

Durable construction built for continuous use

Crafted from GMP-compliant 304 stainless steel and anodized aluminum, the PL-501-NL is built to last in fast-moving production environments. It resists corrosion, cleans easily, and minimizes downtime through simple maintenance and rugged reliability.

For food and beverage producers needing efficient, accurate body and neck labeling, the PL-501-NL delivers dependable performance without slowing you down.

Show More

Show More

PL-501

Wrap Around Labeling System

PL-501

Wrap Around Labeling System

Need a flexible labeler that adapts to round and flat containers?

The PL-501 is designed to apply pressure-sensitive labels to round bottles, jars, and cans with speed and precision. When production calls for flat-surface labeling, a single tap on the touchscreen shifts the system into one-side mode for boxes or rectangular containers. Its smart speed control adjusts automatically based on the container surface for smooth, consistent application.

Easy setup with intuitive controls

The PL-501 makes changeovers fast with a user-friendly interface and built-in guidance. Operators can access on-screen instructions, memory presets, and troubleshooting tips with ease. Hand wheels make mechanical adjustments simple, keeping downtime to a minimum and output high.

Built to last in real-world conditions

Constructed from GMP-compliant 304 stainless steel and anodized aluminum, the PL-501 is ready for tough environments and long production runs. Its clean design and rugged materials make maintenance quick and straightforward, extending the life of your investment.

If your product line includes round or flat containers, the PL-501 gives you the versatility, control, and reliability to keep labeling efficient and accurate.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Dimensions

- Dimensions: L-W-H: 79” x 40” x 41” (2006mm x 1016mm x 1041mm)

- Maximum Label Size: 6” x 11.8” (152mm x 300mm)

- Maximum Container Width: 4” (101mm) *6” (152mm) Optional

- Conveyor Width: 3.25” (82.55mm)

- Conveyor Height: 31.75-47.75” (806-1213mm)

- Spool Diameter: 14” (356mm)

- Inner Core: 3” (76mm)

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

Show More ˅

PL-501 #3 Wind

Right-to-left product flow and #3 label application.

PL-501 #3 Wind

Right-to-left product flow and #3 label application.

Customize Your Labeling Workflow with the PL-501/#3 Wind for Optimal Efficiency

Choosing the right labeling machine for your production line is essential for efficiency and consistency. The PL-501/#3 Wind configuration offers a specialized alternative to the standard PL-501, designed for operations that require a right-to-left product flow and #3 label application. While it maintains the same high-performance specs as the base model, this configuration ensures seamless integration into workflows with different product handling needs.

Key Benefits & Features:

- Right-to-Left Labeling: Ideal for production lines requiring reverse product flow.

- Compatible with #3 Labels: Tailored for applications using #3 labels instead of the standard #4.

- Same Trusted Performance: Maintains all the precision, durability, and efficiency of the base PL-501.

- Seamless Integration: Works with your existing production setup without compromising speed or accuracy.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501/6

6-inch-wide conveyor for wider containers.

PL-501/6

6-inch-wide conveyor for wider containers.

Expand Your Labeling Capacity with the PL-501/6 for Wider Containers

Built with a 6-inch-wide conveyor, the PL-501/6 lets you handle a broader range of container sizes, making it ideal for lines that must accommodate everything from small bottles to large gallon jugs. You get the same trusted functionality of the standard PL-501 with additional room to grow.

Key Benefits & Features

- 6-Inch Conveyor: Accommodates larger or more varied container widths.

- Consistent Wrap-Around Precision: Maintains accurate placement at higher speeds.

- Versatile for Multiple Industries: Commonly used in chemical, food and beverage, and pharmaceutical.

- Easy Changeovers: Adjust for different product widths without losing efficiency.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501/6 #3

Combines 6-inch conveyor with #3 wind (reverse flow).

PL-501/6 #3

Combines 6-inch conveyor with #3 wind (reverse flow).

Combine Wider Conveyors and Reverse Flow in One Efficient System

By merging the 6-inch-wide conveyor with #3 wind (right-to-left flow), the PL-501/6 #3 delivers enhanced flexibility for unique production layouts. Handle bigger containers while integrating seamlessly with workflows oriented in reverse.

Key Benefits & Features

- Wider Conveyor & Reverse Flow: Two specialized features in one configuration.

- Right-to-Left Product Handling: Ideal if your line demands an alternate flow direction.

- High-Volume Capability: Accommodates both larger containers and higher throughput needs.

- Same PL-501 Reliability: Inherits the performance and precision of the base model.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501 3M

3-meter conveyor for added line length for side transfers, screw feed indexers, or integrating upstream components.

PL-501 3M

3-meter conveyor for added line length for side transfers, screw feed indexers, or integrating upstream components.

Extend Your Production Line with the PL-501 3M for Added Conveyor Space

Equipped with a 3-meter conveyor, the PL-501 3M is perfect for operations requiring additional room for side transfers, screw feed indexers, or integrating upstream components. It maintains the PL-501’s reputation for speed and precision while offering more space to accommodate complex setups.

Key Benefits & Features

- 3-Meter Conveyor: Increased space for side transfers or upstream additions.

- Ideal for High-Volume Lines: Great for beverage fillers or where multiple containers feed at once.

- Flexible Integration: Fits easily into existing lines needing extra conveyor length.

- Reliable Performance: Retains all the core labeling accuracy of the standard PL-501.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501 #3 3M

3-meter conveyor plus #3 wind (reverse flow).

PL-501 #3 3M

3-meter conveyor plus #3 wind (reverse flow).

Achieve Reverse Flow and Extended Conveyor in One Versatile Machine

The PL-501 #3 3M combines the 3-meter conveyor with the #3 (right-to-left) wind, providing maximum adaptability in product handling. It’s the solution for facilities requiring added conveyor length alongside a non-traditional product flow.

Key Benefits & Features

- Long Conveyor & Reverse Flow: Ideal for complex production lines with specific layout needs.

- Simplified Side Transfers: More space enables additional upstream or downstream components.

- Maintains PL-501 Efficiency: All the speed and labeling accuracy you expect.

- Reduced Downtime: Streamlined workflow for faster changeovers.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501/6 3M

6-inch-wide, 3‑meter conveyor for larger containers and additional space.

PL-501/6 3M

6-inch-wide, 3‑meter conveyor for larger containers and additional space.

Wider and Longer: The PL-501/6 3M for Heavy-Duty Production Demands

This configuration merges the 6-inch-wide conveyor with a 3-meter length, giving you both the capacity for larger containers and the extra space needed for side transfers or multi-container feeding. If your line handles a broad range of container sizes at scale, the PL-501/6 3M is a perfect fit.

Key Benefits & Features

- 6-Inch, 3-Meter Conveyor: Accommodates large or varied containers while providing extra line length.

- Versatile Application: Adaptable to food, beverage, chemical, or pharma workflows.

- Seamless Integration: Easily fits into high-throughput production lines.

- Retains Base Model Performance: Preserves the accuracy and reliability of the standard PL-501.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501/6 3M #3 Wind

6‑inch-wide, 3‑meter conveyor combined with #3 right‑to‑left flow.

PL-501/6 3M #3 Wind

6‑inch-wide, 3‑meter conveyor combined with #3 right‑to‑left flow.

Maximize Flexibility: Larger, Longer, and Reverse Flow All in One

By blending a 6-inch-wide, 3-meter conveyor with the #3 right-to-left flow, this all-in-one configuration meets the most demanding production requirements. It’s perfect for facilities that handle large containers, need extra conveyor length, and run lines in reverse orientation.

Key Benefits & Features

- Ultimate Versatility: Wider conveyor, extended length, and reverse flow combined.

- Adaptable for Complex Systems: Room for integrations like side transfers or multi-container feeds.

- Efficient Layout: Accommodates non-standard line directions without sacrificing speed.

- Top-Tier Performance: Delivers the same PL-501 precision and reliability.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501-3M-NL

3‑meter conveyor with dual label heads for main + neck labels.

PL-501-3M-NL

3‑meter conveyor with dual label heads for main + neck labels.

Label Bottles with a Neck Label in One Pass Using the PL-501-3M-NL

Designed specifically for neck labels (like beer or specialty beverage bottles), this configuration adds a second label head for precise neck label placement. The extended 3-meter conveyor ensures enough line space for positioning, making it a strong choice for multi-label applications.

Key Benefits & Features

- Dual-Label Capability: Ideal for applying main and neck labels simultaneously.

- 3-Meter Conveyor: Extra space for proper container spacing and positioning.

- Accurate Neck Label Placement: Ensures brand consistency for beverage and specialty products.

- Fully Featured PL-501: Retains the base model’s speed, precision, and easy operation.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501D

Applies crescent‑shaped labels to tapered cups or containers.

PL-501D

Applies crescent‑shaped labels to tapered cups or containers.

Tackle Tapered Containers with the PL-501D for Custom Cup Labeling

Engineered for tapered cups or containers, the PL-501D applies crescent-shaped labels with precision. This specialization is perfect for soup cups, deli containers, or any vessel that narrows toward the bottom.

Key Benefits & Features

- Tapered Cup Labeling: Designed specifically for conical or tapered surfaces.

- Consistent Application: Ensures the label stays flat and wrinkle-free around the taper.

- Brand Versatility: Supports custom ‘rainbow’ or crescent-shaped labels.

- High Throughput: Delivers fast labeling without compromising accuracy.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501-ZDT

Zero‑downtime labeling with alternating dual label heads.

PL-501-ZDT

Zero‑downtime labeling with alternating dual label heads.

Zero Downtime Labeling: Keep Production Moving with the PL-501-ZDT

Featuring two label heads that alternate when one runs out of labels, the PL-501-ZDT virtually eliminates stops for roll changes. Ideal for high-volume lines where every minute of uptime matters.

Key Benefits & Features

- Dual Label Heads: Automatic switching ensures continuous labeling.

- Perfect for Large Runs: Ideal for operations handling high production speeds.

- Minimize Downtime: Swap label rolls on one head while the other keeps working.

- Same PL-501 Reliability: Consistent application and user-friendly controls.

Show More

Labeling Types: Wrap Around, One Side Apply Optional.

Labeling Speed: Maximum Dispensing Speed : 131.2’/min (40m/min)

Maximum Conveyor Speed : 72.2’/min (22m/min) *optional customization

Net Weight

Approx 330 lbs (150 kgs)

Building

Made of 304 stainless steel and anodized aluminum, and carefully treated to guard against the effects of harsher environments.

Power

- Voltage: 110/220 VAC 50/60 HZ 1 Phase

- Power in KW: .700

- Drive: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-501-NL

Inline Horizontal Wrap Around Labeling System

PL-501-NL

Inline Horizontal Wrap Around Labeling System

Need reliable body and neck labeling for round containers?

The PL-501-NL is purpose-built for the food and beverage industry, applying pressure-sensitive labels to bottles and jars with precision. Whether you're labeling the body, the neck, or both, this machine adjusts to your product shape and speed, delivering a clean, consistent finish. Optional front-and-back labeling lets you scale up your presentation without switching machines.

Designed for quick setups and flexible changeovers

The PL-501-NL makes fine-tuning easy with straightforward controls and operator-friendly features. Adjustments for different container sizes or label types can be completed quickly, keeping your team efficient and production on schedule.

Durable construction built for continuous use

Crafted from GMP-compliant 304 stainless steel and anodized aluminum, the PL-501-NL is built to last in fast-moving production environments. It resists corrosion, cleans easily, and minimizes downtime through simple maintenance and rugged reliability.

For food and beverage producers needing efficient, accurate body and neck labeling, the PL-501-NL delivers dependable performance without slowing you down.

Show More

Show More

Popular Add-ons

Tailor your equipment with add-ons for the perfect fit.

Don't settle for generic labeling solutions. Get expert advice tailored to your specific needs.

We're dedicated to helping you achieve maximum efficiency. Contact us now for a free consultation, and let us reveal how our specialized knowledge can transform your labeling process into a competitive advantage.

DESIGNED FOR EFFICIENCY, BUILT FOR PERFORMANCE

This labeling machine streamlines production, reduces waste, and maximizes output. With precision control and fast changeovers, it ensures consistent labeling and minimal downtime. Built for reliability, it keeps your operation running at peak performance.

Portable Design

Unmatched Flexibility in Production Layout

Eliminate production line constraints. The PL-501 mobility allows you to quickly adapt to changing production demands, maximizing floor space and minimizing downtime during line reconfiguration. Easily move the machine to where it’s needed, when it’s needed, allowing you to optimize your workspace.

One-Touch Touchscreen Controls

Simplified Operation and Reduced Training Time

Empower your team with intuitive controls. The one-touch touchscreen minimizes operator error and speeds up setup, reducing training time and ensuring consistent performance, even with less experienced staff. Get your lines running faster and reduce the cost of lengthy training sessions.

Auto Label-Set Function

Consistent Precision and Reduced Label Waste

Say goodbye to inconsistent label placement. The auto label-set feature confirms label sensitivity by detecting the separation between each label. With one push of a button, labeling is set up — and positioned correctly.

Less waste, better-looking products. That's what you get. It saves you money and makes your brand shine.

Touchscreen Control System with Job Memory

Fast Changeovers & Quick Repeat Setups

Minimize downtime between product runs. Store your most common settings and instantly recall them, allowing for fast and efficient changeovers. This feature is ideal for businesses with multiple product lines or frequent batch changes, maximizing production efficiency.

Featured Product Samples

“Pack Leader USA provided a great value for a labeler for a mid-sized operation. They offer dependable quality, service and cost while backed by service to maintain operations.”

FAQ

The PL-501 is designed with versatility in mind, accommodating a wide range of container sizes and shapes. We encourage you to contact our sales team for a free consultation. We can assess your specific product and packaging requirements to ensure the PL-501 is the perfect fit. You can also send us samples for testing.

The PL-501 is engineered for high-speed labeling, with adjustable speed settings to match your production needs. Its reliable performance and quick changeover capabilities ensure minimal downtime and maximum output. We can provide throughput estimations based on your specific application during a consultation.

We provide comprehensive post-purchase support, including technical assistance, troubleshooting, and maintenance guidance. Our dedicated support team is available to answer your questions and resolve any issues promptly.

The PL-501 distinguishes itself through its exceptional portability, user-friendly touchscreen interface, and precise auto label-set function. It's designed for businesses seeking flexibility and efficiency in a compact package. We focus on reliable performance and robust construction. We encourage you to compare our specifications and features directly with other machines to see the PL-501's advantages.

WAYS TO BUY

Get the PL-501 right away with a personalized consultation. We'll figure out the best setup for you and make the purchase smooth, so you can start labeling fast.

Grab the PL-501 with our flexible financing. We'll find a plan that fits your budget, so you can get started and make money without a big upfront cost.

Get the PL-501 now and own it later with our lease-to-own program. It's a smart way to get the equipment you need without the usual banking hassles.

Need the PL-501 for a short time? Our flexible rental program is perfect for you. Get the right equipment for your project without locking yourself into a long-term commitment.