PL Series

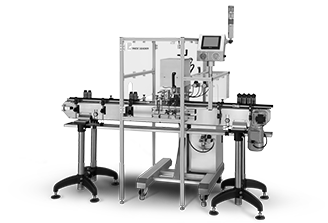

PL-521 Horizontal Wrap Around Labeling System

Labeling slim, unstable containers doesn’t have to slow you down. The PL-521 applies labels with speed and precision across pens, test tubes, lipsticks, and more, giving your line the reliability it needs to perform at its best.

CONFIGURATIONS FOR EVERY PRODUCTION LINE

BUILT FOR FLEXIBILITY. ENGINEERED FOR PRECISION

Whether you're labeling slim tubes or running high-speed production lines, the PL-521 adapts to your operation with effortless precision and unmatched reliability. Compact, flexible, and easy to upgrade, it delivers performance that grows with your business.

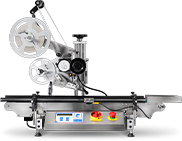

PL-521

Horizontal Wrap Around Labeling System

PL-521X

Horizontal Wrap Labeler no Hopper

PL-521-FVB

Horizontal Wrap Labeler with Feeding Vibration Bowl

PL-521

Horizontal Wrap Around Labeling System

PL‑521 — Horizontal Wrap Labeler with Hopper

Designed for uninterrupted, high‑speed production, the PL‑521 combines a wrap‑around label head with an automatic hopper that continuously feeds slim, non‑freestanding containers—ideal for syringes, ampoules, and similar products.

Key Benefits & Features

- Automatic Hopper Feeding: Hands‑off staging keeps the label head running at full speed for maximum throughput.

- Wider Handling Components: Expanded plates, starwheel, and shaft guide longer tubes without jams.

- Fragile Product Protection: Angled roller conveyor cradles containers to prevent scuffing and skewed labels.

- GMP‑Ready Frame: All 304 stainless steel and anodized aluminum for easy wash‑down and long service life.

Show More

Labeling

Labeling Heads: Single wrap‑around labeling head

Labeling Speed: Dispensing up to 131.2 ft/min (40 m/min); conveyor up to 72.2 ft/min (22 m/min)

Labeling Accuracy: Precision stepper motor‑driven for consistent label placement

Denesting & Stacking

- Stacking Capacity: Compatible with containers ranging from 0.25”–6” in length (6.5 mm–152 mm)

- Compatible Clamshells: Ideal for bottle diameters from 0.3”–1” (7.6 mm–25 mm)

- Feeder Mechanism: Integrated wrap‑around conveyor with 14” (356 mm) spool and 3” (76 mm) inner core for smooth label feeding

Dimensions

- Dimensions L‑W‑H : 78” × 42” × 64” (1981 mm × 1067 mm × 1626 mm)

Power

- Voltage: 110/220 VAC, 50/60 Hz, 1 Phase

- Power Usage: 0.840 kW

- Drive Type: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

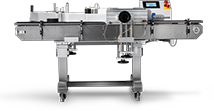

PL-521X

Horizontal Wrap Labeler no Hopper

Customize Your PL-521 Configuration for Seamless Horizontal Labeling

Choosing the right setup for your production line is key to efficient, accurate labeling, especially for small, delicate products like syringes, lipsticks, and test tubes. The PL-521 series offers multiple configurations to match your unique packaging needs, whether you need manual loading, hopper-based feeding, or automated vibration bowl feeding.

Each configuration is purpose-built to support your specific production goals while maintaining the same precision and reliability that defines the PL-521.

Key Benefits & Features:

- Flexible Feeding Options: Choose from hopper, vibration bowl, or manual loading to match your production flow.

- Tailored for Small Cylindrical Products: Each setup is optimized for horizontal wrap labeling of slim, non-freestanding containers.

- Durable and Modular Design: Engineered with stainless steel and anodized aluminum for long-term use and easy cleaning.

- Streamlined Performance: No matter the configuration, you’ll enjoy synchronized controls, consistent labeling, and minimal downtime.

Show More

Show More

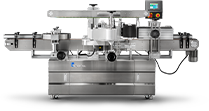

PL-521-FVB

Horizontal Wrap Labeler with Feeding Vibration Bowl

Customize Your PL-521-FVB for Seamless Horizontal Labeling with Vibration Bowl Feeding

The PL-521-FVB configuration is purpose-built for precision horizontal wrap labeling of slim, delicate containers like doob tubes, lip gloss, syringes, and more. Outfitted with an integrated vibration bowl, this system automates product feeding with consistent speed and alignment; ideal for fragile, non-freestanding containers.

Designed to maintain a steady pace of 24–30 bpm, the PL-521-FVB improves labeling accuracy and throughput without sacrificing control or product handling. Whether you're scaling up production or eliminating manual loading inefficiencies, this configuration brings speed and repeatability to your line.

Key Benefits & Features:

- Automated Vibration Bowl Feeding: Reduces labor and enhances flow by automatically orienting and feeding slim tubes directly onto the conveyor for seamless labeling.

- Gentle Handling for Fragile Products: Perfect for small cylindrical containers that can't stand upright. This configuration keeps them horizontal and protected throughout the process.

- Consistent Performance at 24–30 BPM: Keeps up with your production demands while maintaining label precision, even on high-speed runs.

Show More

Show More

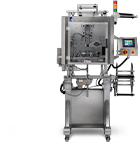

PL-521

Horizontal Wrap Around Labeling System

PL-521

Horizontal Wrap Around Labeling System

PL‑521 — Horizontal Wrap Labeler with Hopper

Designed for uninterrupted, high‑speed production, the PL‑521 combines a wrap‑around label head with an automatic hopper that continuously feeds slim, non‑freestanding containers—ideal for syringes, ampoules, and similar products.

Key Benefits & Features

- Automatic Hopper Feeding: Hands‑off staging keeps the label head running at full speed for maximum throughput.

- Wider Handling Components: Expanded plates, starwheel, and shaft guide longer tubes without jams.

- Fragile Product Protection: Angled roller conveyor cradles containers to prevent scuffing and skewed labels.

- GMP‑Ready Frame: All 304 stainless steel and anodized aluminum for easy wash‑down and long service life.

Show More

Labeling

Labeling Heads: Single wrap‑around labeling head

Labeling Speed: Dispensing up to 131.2 ft/min (40 m/min); conveyor up to 72.2 ft/min (22 m/min)

Labeling Accuracy: Precision stepper motor‑driven for consistent label placement

Denesting & Stacking

- Stacking Capacity: Compatible with containers ranging from 0.25”–6” in length (6.5 mm–152 mm)

- Compatible Clamshells: Ideal for bottle diameters from 0.3”–1” (7.6 mm–25 mm)

- Feeder Mechanism: Integrated wrap‑around conveyor with 14” (356 mm) spool and 3” (76 mm) inner core for smooth label feeding

Dimensions

- Dimensions L‑W‑H : 78” × 42” × 64” (1981 mm × 1067 mm × 1626 mm)

Power

- Voltage: 110/220 VAC, 50/60 Hz, 1 Phase

- Power Usage: 0.840 kW

- Drive Type: Stepper Motor

Controls

- Delta Color Touch Screen

Show More

PL-521X

Horizontal Wrap Labeler no Hopper

PL-521X

Horizontal Wrap Labeler no Hopper

Customize Your PL-521 Configuration for Seamless Horizontal Labeling

Choosing the right setup for your production line is key to efficient, accurate labeling, especially for small, delicate products like syringes, lipsticks, and test tubes. The PL-521 series offers multiple configurations to match your unique packaging needs, whether you need manual loading, hopper-based feeding, or automated vibration bowl feeding.

Each configuration is purpose-built to support your specific production goals while maintaining the same precision and reliability that defines the PL-521.

Key Benefits & Features:

- Flexible Feeding Options: Choose from hopper, vibration bowl, or manual loading to match your production flow.

- Tailored for Small Cylindrical Products: Each setup is optimized for horizontal wrap labeling of slim, non-freestanding containers.

- Durable and Modular Design: Engineered with stainless steel and anodized aluminum for long-term use and easy cleaning.

- Streamlined Performance: No matter the configuration, you’ll enjoy synchronized controls, consistent labeling, and minimal downtime.

Show More

Show More

PL-521-FVB

Horizontal Wrap Labeler with Feeding Vibration Bowl

PL-521-FVB

Horizontal Wrap Labeler with Feeding Vibration Bowl

Customize Your PL-521-FVB for Seamless Horizontal Labeling with Vibration Bowl Feeding

The PL-521-FVB configuration is purpose-built for precision horizontal wrap labeling of slim, delicate containers like doob tubes, lip gloss, syringes, and more. Outfitted with an integrated vibration bowl, this system automates product feeding with consistent speed and alignment; ideal for fragile, non-freestanding containers.

Designed to maintain a steady pace of 24–30 bpm, the PL-521-FVB improves labeling accuracy and throughput without sacrificing control or product handling. Whether you're scaling up production or eliminating manual loading inefficiencies, this configuration brings speed and repeatability to your line.

Key Benefits & Features:

- Automated Vibration Bowl Feeding: Reduces labor and enhances flow by automatically orienting and feeding slim tubes directly onto the conveyor for seamless labeling.

- Gentle Handling for Fragile Products: Perfect for small cylindrical containers that can't stand upright. This configuration keeps them horizontal and protected throughout the process.

- Consistent Performance at 24–30 BPM: Keeps up with your production demands while maintaining label precision, even on high-speed runs.

Show More

Show More

Popular Add-ons

Enhance your equipment to suit your unique needs.

Don't settle for generic labeling solutions. Get expert advice tailored to your specific needs.

We're dedicated to helping you achieve maximum efficiency. Contact us now for a free consultation, and let us reveal how our specialized knowledge can transform your labeling process into a competitive advantage.

UNMATCHED LABELING PRECISION AND FLEXIBILITY TO FIT YOUR PRODUCTION NEEDS

The PL-521 is built to solve real-world labeling challenges, offering reliable accuracy, easy customization, and seamless integration to keep your production running smoothly.

Engineered for Slim, Cylindrical Products

Reliable Labeling for Hard-to-Handle Containers

The PL-521’s distinctive angled roller conveyor is purpose-built for horizontal labeling of non-freestanding products like pens, test tubes, and syringes, ensuring precision even with fragile or awkward items.

Simple Controls, Smarter Workflow

Streamlined Setup and Operation

With a user-friendly touchscreen, 30-job memory, and built-in troubleshooting guides, operators can reduce setup time and changeover effort, keeping production moving with fewer interruptions.

Built to Last in Demanding Environments

Maximum Uptime, Minimal Maintenance

Constructed from GMP-compliant 304 stainless steel and anodized aluminum, the PL-521 resists corrosion and wear, making it a durable solution that supports long-term operational reliability.

Adaptable Features for Changing Needs

Future-Ready Flexibility

From its one-button teach sensor to easy printer integration, the PL-521 is designed to scale with your production, whether you're switching label sizes or adding product codes.

FAQ

Absolutely. With built-in instructions, memory presets, troubleshooting guides, and intuitive handwheel adjustments, the PL-521 is incredibly user-friendly. It’s also built with durable stainless steel and anodized aluminum for easy cleaning and long-term reliability.

Yes. The PL-521 features fully synchronized controls and stepper motors for high-speed, precise labeling. Productivity tools like preset label counts, production run tracking, and a job memory system help you meet your output goals without losing momentum.

Unlike standard labelers, the PL-521 handles horizontal labeling with precision. It’s engineered for delicate, non-freestanding items that other machines may struggle with. Plus, it’s flexible enough to handle semi-automatic or in-line production and offers easy upgrades for coding and customization.

WAYS TO BUY

Get the PL-521 right away with a personalized consultation. We'll figure out the best setup for you and make the purchase smooth, so you can start labeling fast.

Grab the PL-521 with our flexible financing. We'll find a plan that fits your budget, so you can get started and make money without a big upfront cost.

Get the PL-521 now and own it later with our lease-to-own. It's a smart way to get the equipment you need without the usual banking hassles.

Need the PL-521 for a short time? Our rental program is perfect. Get the right equipment for your project without a long-term commitment.