PL Series

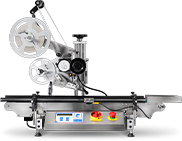

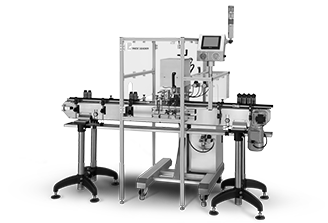

PL-211 Top Labeling Machine

Struggling with high-volume labeling? Need a faster, more accurate solution? The PL-211 is designed for flexible productivity and consistent, high-speed performance.

.png?width=460&height=440&name=Labeling-Equipment_PL-211_FC%20(1).png)

CONFIGURATIONS FOR EVERY PRODUCTION LINE

ENGINEERED FOR HIGH-SPEED TOP LABELING ON BOXES, CARTONS, BAGS, AND JARS

Speed up your workflow and reduce labeling errors with the PL-211. It delivers precise application at high speeds and simplifies changeovers between product runs.

PL-211

Top Labeling System

PL-211CS

Tamper-Evident C-Wrap Label

PL-211D-BL

Automated Bag Labeling

PL-211-D

Top Labeler with Hugger Belts

PL-211

Top Labeling System

The PL-211 Top Labeling System is built for fast, accurate application on boxes, cartons, bags, and jars — helping you maintain high output without sacrificing precision. Engineered for demanding environments, its durable stainless steel construction, quick-adjust handwheels, and touchscreen interface make operation smooth and changeovers fast.

From preset run counters to one-button label teaching and printer-ready integration, the PL-211 is your go-to solution for consistent labeling and reduced waste, all with seamless inline compatibility.

Effortless Setup

Get up and running quickly with our intuitive auto label-set feature. Simply push a button, and the system intelligently detects and configures label spacing for immediate, accurate labeling.

High-Speed Precision

Experience rapid labeling without sacrificing accuracy, crucial for high-volume production. The PL-211's design minimizes downtime and significantly boosts throughput to meet demanding production schedules reliably.

Seamless Changeovers

Minimize downtime with the PL-211's streamlined and intuitive changeover process. Easy handwheel adjustments and a user-friendly interface allow for quick transitions between different label types and sizes, with saved settings for future efficiency.

Adaptable Integration

Flawlessly incorporate optional printing capabilities with built-in thermal or hot-foil printer controls. This integrated design ensures synchronized operation and precise code placement directly onto your labels.

Real-Time Tracking

Monitor your production progress with comprehensive built-in counters. Easily track the total production run, the current label count, and set specific production targets for efficient batch management.

Show More

Label Type

- Top

- Wrap Around Clamshell Optional

Speed

- Maximum Dispensing Speed : 131.2’/min (40m/min)

- Maximum Conveyor Speed : 131.2’/min (40m/min)

Dimensions

- Dimensions L-W-H : 50.5” x 29.5” x 62” (1283mm x 750 mm x 1575 mm)

- Maximum Label Size : 6” x 11.8” (152mm x 300mm)

- Maximum Container Width : 8.5” (216mm)

- Maximum Container Height : 7.5” (Flat 191mm)

- Conveyor Width : 6.25” (159mm) *optional widths available

- Conveyor Height : 29.5-39.5” (749-1003mm)

- Spool Diameter : 14” (356mm)

- Inner Core : 3” (76mm)

Power

- Voltage : 110/220 VAC 50/60 HZ 1 Phase

- Power in KW : .700

- Drive : Stepper Motor

- Net Weight : Approx 265 lbs (120 kgs)

- Controls : Delta Color Touch Screen

Show More

Show More ˅

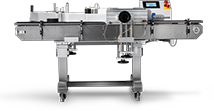

PL-211CS

Tamper-Evident C-Wrap Label

Seal & Secure: The Versatile PL-211CS Clamshell Labeling System

Ensure product integrity and enhance presentation with the PL-211CS. This innovative labeling system is specifically designed for clamshell packaging, applying tamper-evident C-wrap labels to the front for secure closure. Its unique split-belt conveyor allows for precise bottom-up label application, and with its adaptable design, the PL-211CS can also handle top and bottom labeling tasks, offering unparalleled versatility for your packaging needs.

Key Benefits & Features:

- Secure Tamper Evident Labeling: Applies C-wrap labels to the front of clamshells, creating a reliable tamper-evident seal for enhanced product security and consumer confidence.

- Versatile Application Capabilities: Beyond clamshells, the PL-211CS can efficiently apply top, bottom, or both top and bottom labels to a wide range of container styles.

- Precise Bottom-Up Labeling: The specialized split-belt conveyor facilitates accurate bottom-up application, ensuring consistent and professional label placement, especially for C-wrap labels.

Show More

Show More

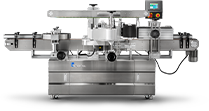

PL-211D-BL

Automated Bag Labeling

Automated Bag Labeling Efficiency for High-Volume Production

Streamline your bag labeling process with the PL-211D-BL. Extremely compatible with the cannabis industry and beyond, this system features an integrated bag feeder and secure hold-downs to ensure consistent and accurate top label application on flexible packaging. Adding an accumulation device further enhances efficiency by organizing labeled bags for downstream processing, optimizing your production workflow.

Key Benefits & Features:

- Integrated Bag Feeding System: Automates the labeling process by efficiently feeding individual bags directly into the labeling station, reducing manual handling and increasing throughput.

- Secure Bag Hold-Downs & Consistent Application: Ensures stable bag positioning during labeling, guaranteeing accurate and wrinkle-free top label placement, crucial for maintaining product presentation and compliance.

- Automated Accumulation Device: Organizes and collects labeled bags after application, facilitating smooth transitions to subsequent packaging or handling stages, boosting overall line efficiency.

Show More

Show More

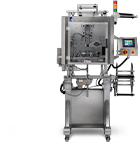

PL-211-D

Top Labeler with Hugger Belts

Labeling Versatility: The PL-211-D Top Labeler with Hugger Belts

Experience unparalleled flexibility in your labeling operations with the PL-211-D. Unlike standard side-belt configurations, its innovative hugger belt design with a wider central gap securely conveys a broader range of product sizes. This adaptability allows for precise application of C-wrap labels, providing tamper evidence across various container widths. Furthermore, the PL-211-D retains the capability for accurate top and bottom labeling, making it a more versatile solution than dedicated clamshell labelers.

Key Benefits & Features:

- Enhanced Product Size Versatility: The wider gap and secure hugger belts accommodate a greater variety of product widths, enabling C-wrap labeling on diverse container dimensions.

- Flexible C-Wrap and Top/Bottom Labeling: Capable of applying tamper-evident C-wrap labels across a wider product range, as well as standard top and bottom labels, offering multi-application functionality.

- Secure Product Handling: The hugger belt system firmly grips and guides products across the labeling point, ensuring consistent and accurate label placement, even on irregularly shaped items.

Show More

Show More

PL-211

Top Labeling System

PL-211

Top Labeling System

The PL-211 Top Labeling System is built for fast, accurate application on boxes, cartons, bags, and jars — helping you maintain high output without sacrificing precision. Engineered for demanding environments, its durable stainless steel construction, quick-adjust handwheels, and touchscreen interface make operation smooth and changeovers fast.

From preset run counters to one-button label teaching and printer-ready integration, the PL-211 is your go-to solution for consistent labeling and reduced waste, all with seamless inline compatibility.

Effortless Setup

Get up and running quickly with our intuitive auto label-set feature. Simply push a button, and the system intelligently detects and configures label spacing for immediate, accurate labeling.

High-Speed Precision

Experience rapid labeling without sacrificing accuracy, crucial for high-volume production. The PL-211's design minimizes downtime and significantly boosts throughput to meet demanding production schedules reliably.

Seamless Changeovers

Minimize downtime with the PL-211's streamlined and intuitive changeover process. Easy handwheel adjustments and a user-friendly interface allow for quick transitions between different label types and sizes, with saved settings for future efficiency.

Adaptable Integration

Flawlessly incorporate optional printing capabilities with built-in thermal or hot-foil printer controls. This integrated design ensures synchronized operation and precise code placement directly onto your labels.

Real-Time Tracking

Monitor your production progress with comprehensive built-in counters. Easily track the total production run, the current label count, and set specific production targets for efficient batch management.

Show More

Label Type

- Top

- Wrap Around Clamshell Optional

Speed

- Maximum Dispensing Speed : 131.2’/min (40m/min)

- Maximum Conveyor Speed : 131.2’/min (40m/min)

Dimensions

- Dimensions L-W-H : 50.5” x 29.5” x 62” (1283mm x 750 mm x 1575 mm)

- Maximum Label Size : 6” x 11.8” (152mm x 300mm)

- Maximum Container Width : 8.5” (216mm)

- Maximum Container Height : 7.5” (Flat 191mm)

- Conveyor Width : 6.25” (159mm) *optional widths available

- Conveyor Height : 29.5-39.5” (749-1003mm)

- Spool Diameter : 14” (356mm)

- Inner Core : 3” (76mm)

Power

- Voltage : 110/220 VAC 50/60 HZ 1 Phase

- Power in KW : .700

- Drive : Stepper Motor

- Net Weight : Approx 265 lbs (120 kgs)

- Controls : Delta Color Touch Screen

Show More

Show More ˅

PL-211CS

Tamper-Evident C-Wrap Label

PL-211CS

Tamper-Evident C-Wrap Label

Seal & Secure: The Versatile PL-211CS Clamshell Labeling System

Ensure product integrity and enhance presentation with the PL-211CS. This innovative labeling system is specifically designed for clamshell packaging, applying tamper-evident C-wrap labels to the front for secure closure. Its unique split-belt conveyor allows for precise bottom-up label application, and with its adaptable design, the PL-211CS can also handle top and bottom labeling tasks, offering unparalleled versatility for your packaging needs.

Key Benefits & Features:

- Secure Tamper Evident Labeling: Applies C-wrap labels to the front of clamshells, creating a reliable tamper-evident seal for enhanced product security and consumer confidence.

- Versatile Application Capabilities: Beyond clamshells, the PL-211CS can efficiently apply top, bottom, or both top and bottom labels to a wide range of container styles.

- Precise Bottom-Up Labeling: The specialized split-belt conveyor facilitates accurate bottom-up application, ensuring consistent and professional label placement, especially for C-wrap labels.

Show More

Show More

PL-211D-BL

Automated Bag Labeling

PL-211D-BL

Automated Bag Labeling

Automated Bag Labeling Efficiency for High-Volume Production

Streamline your bag labeling process with the PL-211D-BL. Extremely compatible with the cannabis industry and beyond, this system features an integrated bag feeder and secure hold-downs to ensure consistent and accurate top label application on flexible packaging. Adding an accumulation device further enhances efficiency by organizing labeled bags for downstream processing, optimizing your production workflow.

Key Benefits & Features:

- Integrated Bag Feeding System: Automates the labeling process by efficiently feeding individual bags directly into the labeling station, reducing manual handling and increasing throughput.

- Secure Bag Hold-Downs & Consistent Application: Ensures stable bag positioning during labeling, guaranteeing accurate and wrinkle-free top label placement, crucial for maintaining product presentation and compliance.

- Automated Accumulation Device: Organizes and collects labeled bags after application, facilitating smooth transitions to subsequent packaging or handling stages, boosting overall line efficiency.

Show More

Show More

PL-211-D

Top Labeler with Hugger Belts

PL-211-D

Top Labeler with Hugger Belts

Labeling Versatility: The PL-211-D Top Labeler with Hugger Belts

Experience unparalleled flexibility in your labeling operations with the PL-211-D. Unlike standard side-belt configurations, its innovative hugger belt design with a wider central gap securely conveys a broader range of product sizes. This adaptability allows for precise application of C-wrap labels, providing tamper evidence across various container widths. Furthermore, the PL-211-D retains the capability for accurate top and bottom labeling, making it a more versatile solution than dedicated clamshell labelers.

Key Benefits & Features:

- Enhanced Product Size Versatility: The wider gap and secure hugger belts accommodate a greater variety of product widths, enabling C-wrap labeling on diverse container dimensions.

- Flexible C-Wrap and Top/Bottom Labeling: Capable of applying tamper-evident C-wrap labels across a wider product range, as well as standard top and bottom labels, offering multi-application functionality.

- Secure Product Handling: The hugger belt system firmly grips and guides products across the labeling point, ensuring consistent and accurate label placement, even on irregularly shaped items.

Show More

Show More

Popular Add-ons

Tailor your equipment with add-ons for the perfect fit.

Don't settle for generic labeling solutions. Get expert advice tailored to your specific needs.

We're dedicated to helping you achieve maximum efficiency. Contact us now for a free consultation, and let us reveal how our specialized knowledge can transform your labeling process into a competitive advantage.

PERFORMANCE DRIVEN LABELER FOR DEMANDING OPERATIONS

The PL-211 delivers fast, precise top labeling that keeps production moving. Simple changeovers make it easy to handle multiple product lines, while the optional tamper-evident feature adds flexibility and product integrity without slowing output.

ACCURATE LABELING ACROSS ALL TYPES

CONSISTENT LABELING, ANY CONTAINER.

Tired of inconsistent labeling across your diverse product line? The PL-211 is engineered for pinpoint accuracy, regardless of container shape or size, ensuring a professional finish every time. Scale your production without sacrificing label placement quality, thanks to its high-speed capabilities. Plus, benefit from swift and simple changeovers between different labels and containers, and add an extra layer of security with our optional secure sealing for clamshell packaging.

PRECISE TOP LABELING WITH QUICK CHANGEOVERS

PEAK LABELING EFFICIENCY FOR YOUR PRODUCTS

Do you suffer production bottlenecks caused by slow or inaccurate labeling? The PL-211 Top Labeling System is engineered for high-speed operation without compromising accuracy. Its intuitive design ensures swift transitions between container types and sizes, minimizing downtime and maximizing your output. Plus, easily integrate tamper-evident labeling for enhanced product security and consumer confidence.

THE PL-211 ADAPTS TO YOUR EVOLVING NEEDS

FLAWLESS TOP LABELING WITH UNMATCHED VERSATILITY

If you struggle with labeling various product tops efficiently, the PL-211 offers exceptional flexibility, handling trays, boxes, bags, and even bottles with ease. Its simple setup and adjustment features allow for quick adaptation to different container sizes and label requirements. The option to apply tamper-evident labels provides an added layer of security and brand protection for your products.

HIGH-SPEED TOP LABELING WITH OPTIONAL TAMPER-EVIDENT

Labeling Power Designed for High Output

Need a labeling solution that keeps up with production demands? The PL-211 delivers rapid, precise top labeling for a wide range of containers. Its straightforward design makes changeovers quick and simple, helping you maintain efficiency across product lines.

The optional tamper-evident feature adds an extra layer of product integrity, giving customers confidence in every package.

Featured Product Samples

FAQ

WAYS TO BUY

Get the PL-211 right away with a personalized consultation. We'll figure out the best setup for you and make the purchase smooth, so you can start labeling fast.

Grab the PL-211 with our flexible financing. We'll find a plan that fits your budget, so you can get started and make money without a big upfront cost.

Get the PL-211 now and own it later with our lease-to-own program. It's a smart way to get the equipment you need without the usual banking hassles.

Need the PL-211 for a short time? Our flexible rental program is perfect for you. Get the right equipment for your project without locking yourself into a long-term commitment.

Not Sure Which Labeling Machine is Right?

Talk to an Expert for Free.

Not sure which labeler is the right fit? We’ll review your process, identify what you need, and recommend a solution that improves production, reduces waste, and increases efficiency. No pressure, no commitment.

.png?width=350&height=400&name=Link%20(1).png)

.jpg?width=640&height=640&name=sklenarik_beef_jerky_full%20(1).jpg)