You should trust your labeler as much as your customers trust your food.

Your labeler machine should be able to handle clamshell packaging and keep pace with the rest of your packaging equipment. You shouldn’t have to worry about bottlenecks, jams, hard-to-find parts, poor service, and confusing controls. If you have a labeler like that on your line right now, change it out! And if you’re relying on hand labeling, then you’ve got a bottleneck in your production line that’s keeping it from peak efficiency.

As a producer of meal kits, you know trust is paramount to the customer experience. Customers expect their food to arrive fresh, safe to eat, and on time. If they can’t expect any of those things, they won’t be back. So too, should you be able to trust your equipment.

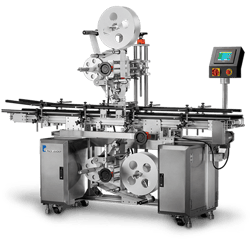

Let’s explore Pack Leader USA clamshell labeler machines to transform your packaging line.

Universal Features and Benefits

While Pack Leader USA has different series of labeling equipment (ELF Series, PL Series, and PRO Series) focused on particular labels or container types, there are features that are common to all of them:

- Simple to use controls

- 304 stainless steel and brushed aluminum construction following Good Manufacturing Practices (GMP) standards

- Modular expandability with add-ons like label printers

- Stepper motors to ensure accurate label placement

- Simple to maintain and repair

- Excellent 24/7 service

When you buy a Pack Leader USA labeler, you’re entering into a partnership. We stand behind our labelers so you can get the best performance from your packaging line.

PL-211D Clamshell Packaging + Top Labeling Machine

The PL-211D is part of Pack Leader USA’s mid-tier labeling system. It’s larger and more functional than the entry-level ELF Series labelers but doesn’t have all the bells and whistles that make the PRO Series more suited to larger operations. They can handle 40 containers per minute and handle containers up to 7.5” tall and 8.5” wide.

The PL-211D is part of Pack Leader USA’s mid-tier labeling system. It’s larger and more functional than the entry-level ELF Series labelers but doesn’t have all the bells and whistles that make the PRO Series more suited to larger operations. They can handle 40 containers per minute and handle containers up to 7.5” tall and 8.5” wide.

If 40 labels per minute doesn’t sound like a lot on paper, realize that’s not far from 1 label per second. Hand labeling can’t even come close. And if you opt for an add-on printer, then you can customize your labels for each customer. Let’s say you’re doing a run of salads. You could program your label printer to put the customer’s name on the label with a message, such as, “Enjoy your salad, Dave!”

Like all the labelers in the PL and PRO line, the PL-211D is on wheels in case you need to move it from one location to the other. It can be used in-line or out of line and can operate automatically or semi-automatically.

PL-221D Clamshell Packaging + Top & Bottom Labeling Machine

Stepping up to the PL-221D could be a massive boost to your productivity. It can accommodate larger packages than the PL-211D, with a max size of 9” tall by 12” wide. It still runs at 40 containers per minute, but remember, this labeler can handle top and bottom at once. Let’s say you do a run of clamshell containers and then need to label some boxed meal kits, as well. With a labeling machine that handles just the top, you’d have to run the boxes through a second time to take care of the bottom. With the PL-22D, you can do both top and bottom labels simultaneously.

Stepping up to the PL-221D could be a massive boost to your productivity. It can accommodate larger packages than the PL-211D, with a max size of 9” tall by 12” wide. It still runs at 40 containers per minute, but remember, this labeler can handle top and bottom at once. Let’s say you do a run of clamshell containers and then need to label some boxed meal kits, as well. With a labeling machine that handles just the top, you’d have to run the boxes through a second time to take care of the bottom. With the PL-22D, you can do both top and bottom labels simultaneously.

Because Pack Leader PL labelers can store different production runs in their memory, the changeover between container types is simple. And since the PL-221D is also on wheels, it can be taken from your clamshell line and moved to your box line if you need it.

PRO-225 Top & Bottom Labeling Machine

Featuring an optional clamshell wrap, the PRO-225 is a truly versatile machine. It can handle 8” by 8” containers and label up to 40 per minute. This is part of the PRO Series, so while you might be seeing those numbers and thinking, “the other machines can do those sizes and speeds,” they aren’t nearly as flexible as the PRO-225 at labeling oddly shaped containers. The label heads can tilt on a 12-degree axis, conforming to tapered or pliable containers. It also has the pinnacle of Pack Leader USA’s auto label-set tech to ensure proper label placement.

Clamshell Packaging Is Worth It

If you've experienced clamshell packaging woes, you may have been considering stepping away from them — but don't abandon them. Clamshells have some excellent benefits:

- They're clear, so customers can see the food before they purchase.

- It protects fresh food without concealing it from view.

- They're recyclable.

- They reduce food waste.

- Tamper evident labels are easy to apply and protect the food while leaving it visible.

Clamshells are an excellent showcase for your food. Think of them as mini-displays for the customer.

Explore Our Clamshell Packaging Labeler Machine Options

Before you put down a sizable down payment on a clamshell packaging labeler machine, ask yourself if the manufacturer is one you trust. When you ask about Pack Leader USA, you’ll consistently find that answer is yes, across many industries. If you’re still pondering over the right labeler for you, check out Pack Leader USA’s Meal Kit Delivery Services Guide to Labeling Equipment. We’ll give you all the advice you need to find the right one for your meal kit packaging line and get those clamshell-covered meals into customers’ hands.

Resources:

.webp?width=200&height=114&name=2x-Packleader-logo-large%20(1).webp)

.webp?width=360&name=2x-color-logo%20(1).webp)